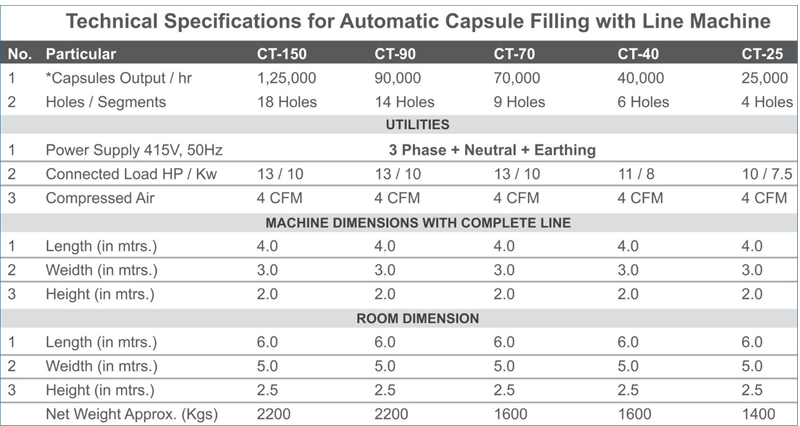

CT 70

Output 70,000 capsules Per/hr

CT 150

Output 1,50,000 capsules Per/hr

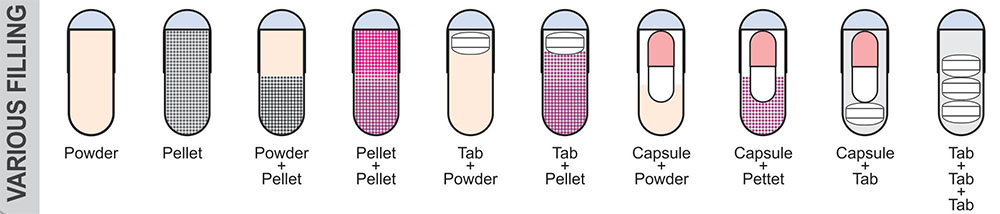

Captech Systems has designed fully automated capsule filling machines for filling powder, pellets granules and tablets separately or in combination such as powder+pellets, pellets+pellets, powder+tablet, pellets+powder+pllets, etc. in hard gelatin capsules. The machines are categorized based on their speeds and are available in capacities ranging from 40,000 capsules per hour up to 1,50,000 capsules per hour.

The powder dosing in achieved using the tamping pin principle wherein the powders are delivered to the capsule body in the form of a slug. The entire process of capsule filling is simplified to ensure automatic capsule alignment, separation, filling & closing, automatic rejection & ejections of un-separated capsules etc. The machine is designed for high filling accuracies and can fill the entire range of hard gelatin capsule sizes from 000 to 5.

The machine design fulfills the latest cGMP standards and allows quick changeover and cleaning with minimal tools.

Our automatic range of capsule filling machines has been designed with our experience spanning close to 2 decades and the technology available with us on secure filling and closing of capsules.

The machine control is by means of a programmable logic controller with touch enable human interface with a very user-friendly operable front end.

- For space – Indexer – Multi Dosing Fillings

- Combination Of Fillings

- Zero Dust *

- Barrier (Resistance) for Toxic Product

- Zero Maintenance

- Easy & Quick Change over

- Vibration

- ERGONOMIC Design

- Small Footprint

- User friendly

Environment :

In Capsule Filling Room humidity and temperature is very important for Empty capsules and products.

Room Temperature: 20° to 25°C

Humidity: 40 to 44% RH

* Output depends upon the quality of capsules, character of the products & environmental conditions.

- cGMP-compliant design and construction.

- Accurate capsule separations without damaging capsules with a wide range of different capsules.

- Automatic ejection system for non-separated / improperly inserted capsule caps.

- High accurate dosing

- Quick fill weight adjustments and high precision dosing tolls ensure optimum machine efficiency

- Easy and simplified size changeovers and low cleaning times.

- Conditions apply

Empty Capsule Sorter

Polishing Sorting Machine

Dust Extractor for Main Machine

Dust Extractor for Polishing

Metal Detector

Filled Capsule Elevator